Characteristics and performance

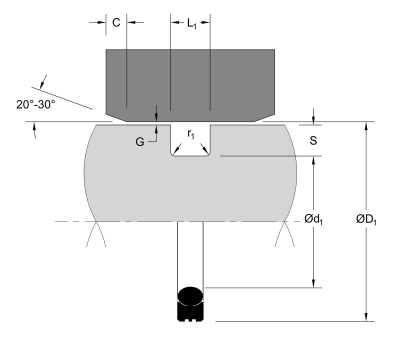

The Hallite SSP is a double-acting, o-ring energized, rotary swivel seal designed to be used to seal outer diameters of shafts, bores, swivels, and other applications with rotating or oscillating movement. The SSP rotary seal has one or two machined grooves in the face ring, depending on the face-ring cross-section, that function to improve sealing against the surface while trapping lubrication and reducing surface contact area, thereby reducing running friction. The o-ring serves to energize the seal face ring, exerting a designed downward force, and also provides static sealing of the housing.

This seal has a specially designed circular inner recess that provides for maximum o-ring contact area to the inner diameter of the seal face, thereby minimizing the possibility of sealing components spinning relative to each other. The standard SSP seal face includes pressure notches, which makes the seal very responsive to changes in pressure. Made from exclusive Hallite Armorlene® 711 or HCF PTFE materials, the SSP rotary seal is energy-efficient due to its low-friction qualities and eliminates any potential sticking on start-up.

High-performance Armorlene® materials, like 711, provide outstanding wear resistance and support a large range of temperature and media compatibilities. The Armorlene® SSP and SSR rotary swivel seals are designed for slow-speed rotary and swivel applications.

Product details

Max pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +44 208 941 2244 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Possible | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |