Meeting expectations for peak hydraulic performance

Storage and handling equipment, engineered systems, industrial trucks, and bulk material handling equipment are just a few examples where equipment is expected to maintain peak performance during long operating cycles of repetitive tasks.

Whether being used to move, store, control, or protect the hydraulic systems and cylinders found in this equipment needed to automate production and facilitate the efficient flow of goods, material handling equipment manufacturers must comply with a number of regulatory requirements because of rising environmental concerns and the demand for eco-friendly equipment.

Working alongside our customers

Hallite design and material engineers work with OEMs to develop components which ensure that their products are safe to use, and meet environmental considerations. Hallite’s high-performance seals, bearings, and ancillary components are designed to enable equipment to meet the performance needs to be able to handle the stress of long performance cycles, repetitive motions, and heavy loads.

Typical applications for mechanical/material handling

| Typical applications | |

| Forklifts, telehandlers, reach stackers | Cranes (mobile, truck-mounted) |

| Aerial work platforms, scissor lifts, etc | Car lifts, cargo lifts, tail lift platforms |

| Recycling / handling equipment, e.g. refuse trucks, scrap shearers, grapples, etc | |

Common mechanical/material handling products

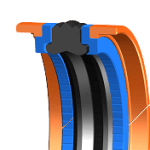

| Rod Seals | ||

|---|---|---|

605 |  621 |  663 |

| Rod seals | ||

605 |  621 |  663 |

Wipers

38 |  844 |  864 |

| Piston seals | |||

714 |  CT |  754 |  780 |

| Bearings | |

506 |  533 |

| Buffer seals |

653 |