Hallite and its sister companies, CDI Energy Products and EGC Critical Components, are recognised leaders in high-performance material development for sealing components and solution.

Because we design and specify our compounds, we have superior control over the properties and performance of our materials.

The broadest range of plastics manufacturing and processing methods enables us to use the most appropriate method per application. We constantly stay on the cutting edge of material development and house an extensive library of existing materials with proven success.

Application of thermoplastics and thermosets includes:

- Sealing components

- Bearings

- Auxiliary devices

- Metal replacement

- Assemblies

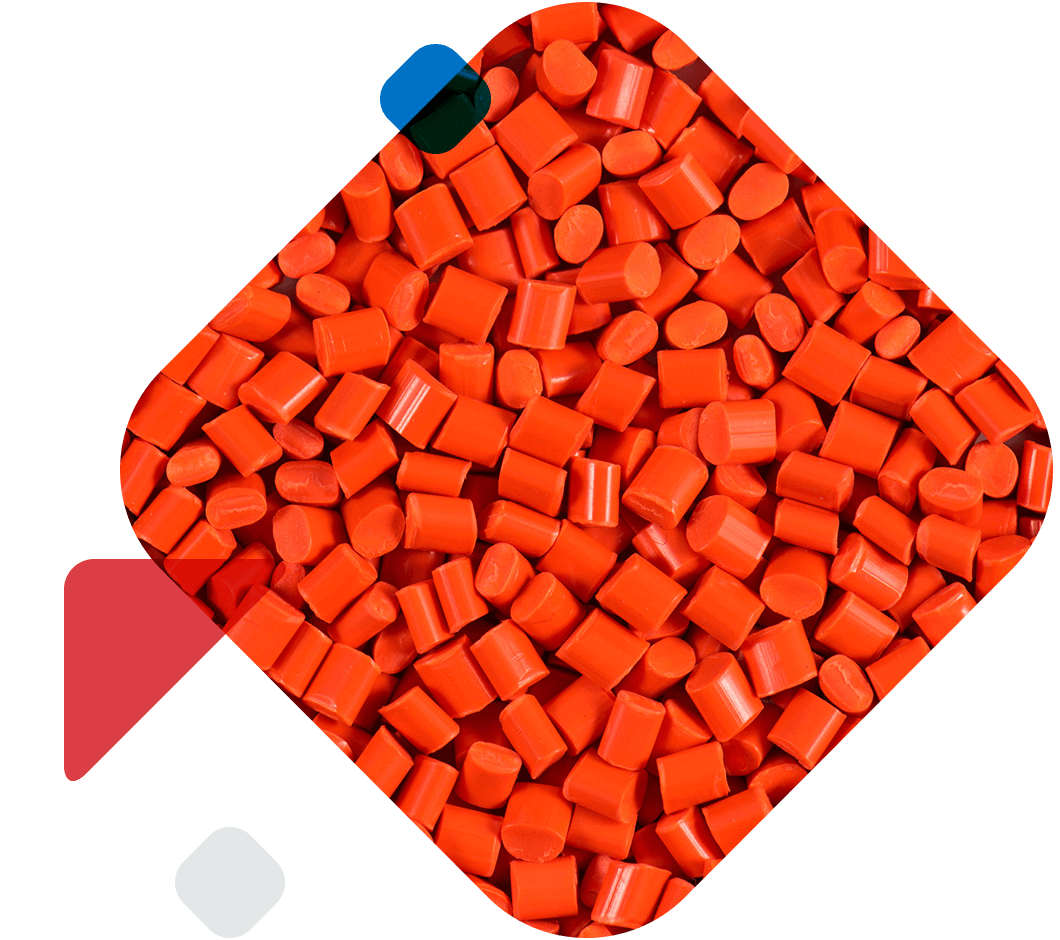

Hallite plastic materials

- Reinforced thermoseting polyester resin

Typically used in Hallite 506 reciprocating bearings - PF – Phenolics

Typically used for reciprocating cylinder bearings - PTFE and filled-PTFE – Polytetrafluoroethylene – Armorlene®

Used in special fluid power and cylinder applications where lower friction properties and a wide range of fluid compatibility is required - PA nylon and filled-nylon – Polyamides

Used in bearings and anti-extrusion elements - PEEK – Polyether ether ketone and similar materials – Victrex®

Recommended for high temperature anti-extrusion elements - UHMWPE – Ultra-high-molecular-weight polyethylene

Recommended for sealing elements where there are poor surface finishes and a high wear resistance is required - POM – Polyoxymethylene – Acetal, Delrin®

Used widely as bearing and anti-extrusion elements - PPS – Polyphenylene sulphide – Ryton®

Used in high-temperature bearing elements

Polymers used in CDI Energy Products and EGC Critical Component products:

- PEK

- PEKEKK

- PVDF (Kynar®)

- CTFE

- PEI (Ultem®)

- PI (Vespel®)

- PE, UHMW

- ETFE (Tefzel®)

- ECTFE (Halar®)

- Polypropylene

- M-PTFE