Pneu-Draulics is based in Nicholasville, Kentucky. The privately-owned company was established in 1982 and purchased by George and Wes Allen in 2010. Over the years, Pneu-Draulics evolved from being a small distributor of a limited supply of sealing devices to a leading ISO-certified distributor and technical services provider of a wide variety of sealing products. The company serves the industrial OEM and MRO markets, supporting customers in aerospace, department of defense (military), oil and gas, heavy-duty mobile, fluid power, chemical, automotive, and mining.

“I started working for Pneu-Draulics in 1988,” said Bobby Kerns, vice president of sales and marketing. “During my career with the company, I’ve held several roles and seen many changes, but our business philosophy is consistent. We are committed to selling only what customers need and providing the best quality products and services with unparalleled support. Manufacturing relationships, like the one we have with Hallite, help us keep our commitment to product and service excellence.”

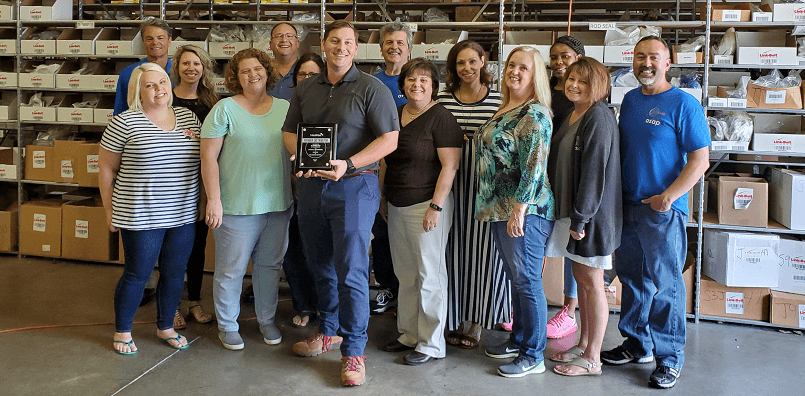

Pneu-Draulics’ staff includes a team of regional managers that collaborate with Hallite to meet customer requirements. Both OEM and MRO customers benefit from having access to best-in-class solutions for engineering challenges.

Sealing extremes

Operational extremes dominate a large percentage of the market Pneu-Draulics supports, requiring fluid power sealing products and solutions designed for very high and low temperatures.

“We support steel, aluminum, chemical plants, and mining facilities. The work environment is getting hotter because equipment is running for longer periods with more aggressive cycles. This presents a range of seal performance challenges,” said Kerns. “Custom-machined seals from Hallite are often used to handle issues encountered with the glycol, water, and steam prevalent in many operations.”

Kerns explained that much steel work happens near furnaces and close to smelting operations using water-based fluids. Sealing materials designed in hydrogenated nitrile butadiene rubber (HNBR) have proven quite useful for this environment. HNBR’s ability to withstand long-term exposure to heat, oil, and chemicals make it a lot more suitable than traditional urethanes. HNBR is just one example of the kinds of sealing material solutions Kerns, and his team has applied in collaboration with Hallite to meet customer operational needs.

In addition to high temperature, crane equipment operators face the opposite extreme — low temperatures. Sealing material designed to withstand subzero exposure, or cold hydraulic fluid flowing through a cylinder, is critically important for these types of environments.

Seal kits for mining

Hallite products and materials for mining seals have a long history and reputation for quality, high-performance, and reliability. This experience coupled with competitive pricing enables Pneu-Drualics to assemble hydraulic cylinder seal kits for mining applications.

“For example, underground operations include roof supports manufactured with hydraulic cylinders. All of the cylinders require seals, so our kits help miners reduce downtime by giving them access to everything they need in one stop,” said Kerns.

“We appreciate the support we get from Hallite. We wouldn’t be able to do this level of work without them. We also love what we do, and we share this passion with our customers and suppliers. It’s a partnership. We treat everyone the way we want to be treated, and when we do this, we grow together.”

For more information about Pneu-Draulics, visit www.pneu-draulics.com. Learn more about the Premier Distributor Program at Hallite.