HiPerDrive Roller Chain

Roller Chain Drives provide a simple, economical and flexible mechanism to transmit power on low speed, high torque drives.

Transeals stock a comprehensive range of roller chains, sprockets, idlers and tensioners.

British Standard Roller Chain

| Simplex | Duplex | Triplex | Common Dimensions | ||||||||

| Chain Type | L, Pin Length | Chain Type | L, Pin Length | Chain Type | L, Pin Length | P Pitch | R Roller Ø | D Pin Ø | W Width | H Height | C |

| 05B-1 | 0.340 | — | — | — | — | 0.315 | 0.197 | — | 0.118 | 0.222 | — |

| 06B-1 | 0.500 | 06B-2 | 0.897 | 06B-3 | 1.300 | 0.375 | 0.250 | 0.129 | 0.225 | 0.323 | 0.403 |

| 08B-1 | 0.658 | 08B-2 | 1.206 | 08B-3 | 1.752 | 0.500 | 0.335 | 0.175 | 0.305 | 0.457 | 0.548 |

| 10B-1 | 0.748 | 10B-2 | 1.402 | 10B-3 | 2.060 | 0.625 | 0.400 | 0.200 | 0.380 | 0.571 | 0.653 |

| 12B-1 | 0.878 | 12B-2 | 1.683 | 12B-3 | 2.402 | 0.750 | 0.475 | 0.225 | 0.460 | 0.626 | 0.766 |

| 16B-1 | 1.382 | 16B-2 | 2.642 | 16B-3 | 3.914 | 1.000 | 0.625 | 0.325 | 0.670 | 0.792 | 1.255 |

| 20B-1 | 1.582 | 20B-2 | 3.020 | 20B-3 | 4.466 | 1.250 | 0.750 | 0.400 | 0.770 | 1.024 | 1.435 |

| 24B-1 | 2.100 | 24B-2 | 4.010 | 24B-3 | 5.914 | 1.500 | 1.000 | 0.576 | 1.000 | 1.315 | 1.904 |

| 28B-1 | 2.563 | 28B-2 | 4.909 | 28B-3 | 7.256 | 1.750 | 1.100 | 0.625 | 1.220 | 1.440 | 2.345 |

| 32B-1 | 2.567 | 32B-2 | 4.882 | 32B-3 | 7.190 | 2.000 | 1.150 | 0.701 | 1.220 | 1.642 | 2.305 |

American Standard Roller Chain

| Simplex | Duplex | Triplex | Common Dimensions | ||||||||

| Chain Type | L, Pin Length | Chain Type | L, Pin Length | Chain Type | L, Pin Length | P Pitch | R Roller Ø | D Pin Ø | W Width | H Height | C |

| 25-1 | 0.296 | — | — | — | — | 0.250 | 0.130 | 0.090 | 0.125 | 0.230 | — |

| 35-1 | 0.466 | 35-2 | 0.864 | 35-4 | 1.260 | 0.375 | 0.200 | 0.141 | 0.187 | 0.354 | 0.398 |

| 40-1 | 0.646 | 40-2 | 1.206 | 40-3 | 1.764 | 0.500 | 0.312 | 0.156 | 0.312 | 0.463 | 0.567 |

| 50-1 | 0.800 | 50-2 | 1.504 | 50-3 | 2.232 | 0.625 | 0.400 | 0.200 | 0.375 | 0.577 | 0.712 |

| 60-1 | 1.000 | 60-2 | 1.890 | 60-3 | 2.772 | 0.750 | 0.469 | 0.234 | 0.500 | 0.691 | 0.898 |

| 80-1 | 1.276 | 80-2 | 2.425 | 80-3 | 3.579 | 1.000 | 0.625 | 0.312 | 0.625 | 0.921 | 1.153 |

| 100-1 | 1.544 | 100-2 | 2.950 | 100-3 | 4.360 | 1.250 | 0.750 | 0.375 | 0.750 | 1.154 | 1.409 |

| 120-1 | 1.942 | 120-2 | 3.740 | 120-3 | 5.531 | 1.500 | 0.875 | 0.437 | 1.000 | 1.382 | 1.787 |

| 140-1 | 2.120 | 140-2 | 4.055 | 140-3 | 5.966 | 1.750 | 1.000 | 0.500 | 1.000 | 1.610 | 1.925 |

| 160-1 | 2.524 | 160-2 | 4.828 | 160-3 | 7.146 | 2.000 | 1.125 | 0.562 | 1.250 | 1.839 | 2.303 |

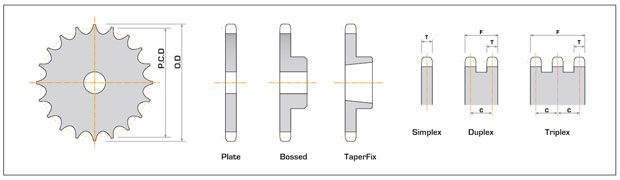

HiPerDrive Sprockets

Transeals stock a comprehensive range of sprockets. All are precision cut and most feature induction hardened teeth. For most applications, Transeals reccomend TaperFix sprockets for their ease of fitment and positive drive. Many special configurations can be manufactured for OEM applications.

British Standard Sprockets

| Chain | 06B | 08B | 10B | 12B | 16B | 20B | 24B | 28B | 32B |

| Pitch | 0.375 | 0.500 | 0.625 | 0.750 | 1.000 | 1.250 | 1.500 | 1.750 | 2.000 |

| T Simplex | 0.209 | 0.284 | 0.361 | 0.437 | 0.637 | 0.731 | 0.950 | 1.159 | 1.159 |

| T Duplex & Triplex | 0.205 | 0.278 | 0.346 | 0.419 | 0.610 | 0.701 | 0.910 | 1.110 | 1.110 |

| F Duplex | 0.608 | 0.826 | 0.999 | 1.185 | 1.865 | 2.136 | 2.814 | 3.455 | 3.415 |

| F Triplex | 1.011 | 1.374 | 1.652 | 1.951 | 3.120 | 3.571 | 4.718 | 5.800 | 5.720 |

| C | 0.403 | 0.548 | 0.653 | 0.766 | 1.255 | 1.435 | 1.904 | 2.345 | 2.305 |

| PCD Per Tooth * | 0.120 | 0.159 | 0.199 | 0.239 | 0.319 | 0.398 | 0.478 | 0.558 | 0.637 |

| OD = PCD + ** | 0.19 | 0.26 | 0.36 | 0.42 | 0.55 | 0.68 | 0.81 | 0.97 | 1.10 |

American Standard Sprockets

| Chain | 35 | 40 | 50 | 60 | 80 | 100 | 120 | 140 | 160 |

| Pitch | 0.375 | 0.500 | 0.625 | 0.750 | 1.000 | 1.250 | 1.500 | 1.750 | 2.000 |

| T Simplex | 0.175 | 0.291 | 0.356 | 0.475 | 0.594 | 0.713 | 0.950 | 0.950 | 1.187 |

| T Duplex & Triplex | 0.171 | 0.285 | 0.349 | 0.465 | 0.581 | 0.698 | 0.930 | 0.930 | 1.163 |

| F Duplex | 0570 | 0.851 | 1.062 | 1.362 | 1.735 | 2.106 | 2.719 | 2.854 | 3.468 |

| F Triplex | 0.969 | 1.417 | 1.775 | 2.259 | 2.888 | 3.513 | 4.508 | 4.778 | 5.733 |

| C | 0.399 | 0.566 | 0.713 | 0.897 | 1.153 | 1.408 | 1.789 | 1.924 | 2.305 |

| PCD Per Tooth * | 0.120 | 0.159 | 0.199 | 0.239 | 0.319 | 0.398 | 0.478 | 0.558 | 0.637 |

| OD = PCD + ** | 0.19 | 0.26 | 0.36 | 0.42 | 0.55 | 0.68 | 0.81 | 0.97 | 1.10 |

* Calculating the PCD with this method can result in a small variation from the exact PCD. The exact PCD can be calculated using the formula:

** Approximate figure only for calculating space requirements for sprockets.