Characteristics and performance

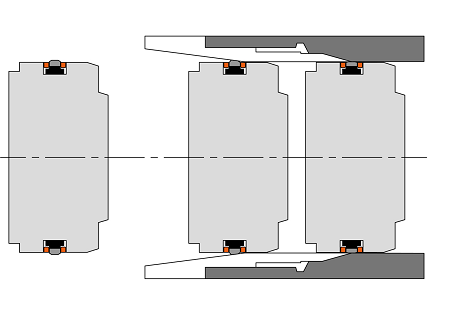

The Hallite 730 double-acting piston seal in a four part assembly is designed for use in heavy-duty applications where position holding ability is important, such as longwall mining roof support applications using water-based fluids and large diameter crane cylinders using standard hydraulic oils.

Comprised of a tough, wear resistant thermoplastic polyester elastomer (TPE) face seal pre-loaded by a profiled nitrile rubber energiser, the Hallite 730 design also contains a pair of rectangular polyacetal anti-extrusion rings.

The standard TPE face material is suitable for both roller-burnished and honed tubing. While rarely used in alternate material, the face material can be provided in a number of material options including lubricated polyester and PTFE.

product details

For your reference, we have included an installation guide for the Hallite 730 double-acting piston seal which you can find after the part number range pages of this data sheet.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +86 (0)21 3351 7272 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Recommended | Recommended |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |