Characteristics and performance

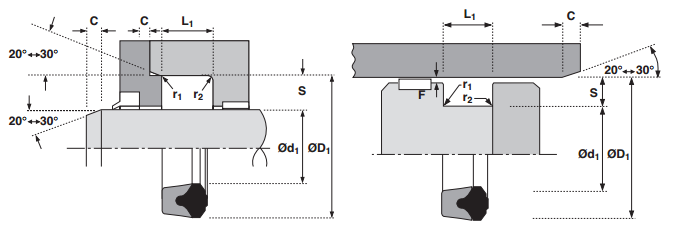

The seal comprises a rubberised fabric U ring to give strength and durability, to which is moulded a rubber header. It is designed to have a controlled pre-load across the angled rubber lips which are accurately trimmed, to ensure a good seal at low pressure.

The seal becomes more effective as the pressure increases and the rubberised fabric deforms to the housing increasing the seal contact area. The surface of the fabric has pockets which retain lubrication to reduce friction and wear.

Product details

The proportions of the range have been determined to give a satisfactory performance when used with the recommended operating conditions. Many other sizes are available outside this range.

The range should be fitted to split housings as shown, but sizes marked* can be fitted to a grooved gland housing, if assembled with care.

NB: Size lists give “on line” tolerances for rod applications.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +86 (0)21 3351 7272 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Recommended |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Recommended | Recommended |

| Water | Possible | Recommended |

| Other fluid types | ||

| Air/Nitrogen | Possible | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Possible | Possible |