Characteristics and performance

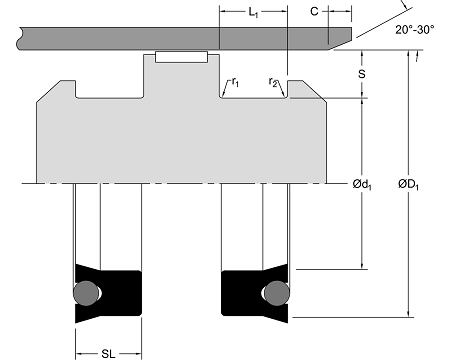

Manufactured in either a polyurethane or polyester shell energised by a high quality O-ring and designed for common North American grooves. The precision trimmed sealing lips ensure optimum sealing action. The deep profile of the Hallite 512 provides extra stability needed to resist rolling in the groove. Together these features result in improved life and sealing.

At zero or low pressure, the O-ring helps to increase the sealing force preventing any bypass. Under most conditions as the pressure rises, the sealing force increases and the O-ring ensures complete lip actuation.

The symmetry of the Hallite 512 makes it ideally suited for single-acting rod and piston applications and its flexibility enables easy installation. The Hallite 512 can also be fitted back-to-back for use in double-acting applications.

Product details

Although the Hallite 512 can be used as a rod seal, other Hallite profiles are more suitable options, such as the Hallite 513, 605, or 621.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +86 (0)21 3351 7272 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |