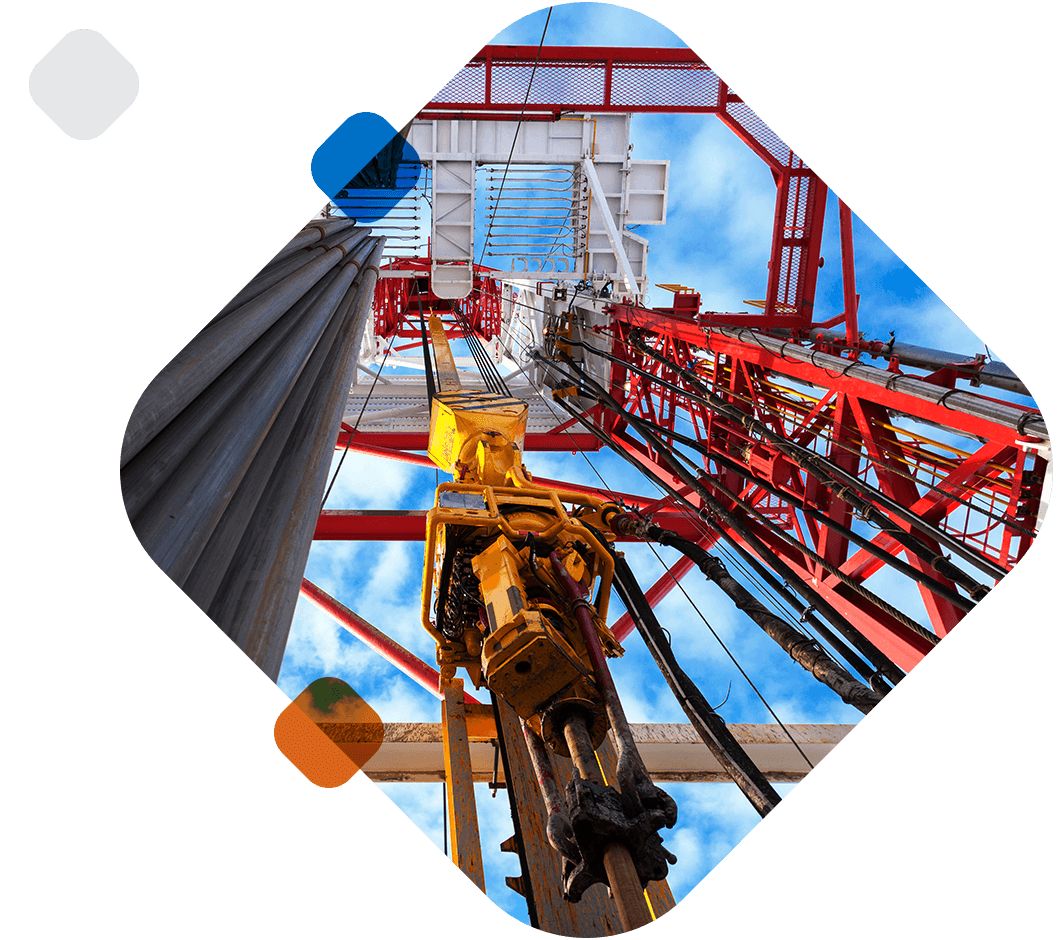

Hallite seals are designed for even the most demanding environments

Well formations have become more difficult to reach and well architecture has become increasingly complex which pushes the conventional operating parameters of critical components and sealing elements. The harsh environments, temperatures, media, and pressures of oil and gas exploration all pose a threat to sealing elements.

For fluid power and hydraulic systems in the oil and gas industry, these severe conditions require that each component is designed and manufactured for optimal performance and to mitigate risk during routine operations.

Agile and flexible to meet oil and gas industry needs

In response to the increasing complexity of extracting hydrocarbons, energy operators and service companies alike look for innovative engineering design that will protect assets, personnel, and the environment.

Our technical team investigates material requirements and operating parameters to meet your application requirements. We offer a range of seal profiles and unique geometries that are application specific.

Typical applications for oil and gas

| Typical applications | |

| Hydraulic (mechanical) roughnecks | Winching systems |

| Hydraulic valve actuators | Wire tensioner systems |

| Motion compensation systems | Position or motion compensators |

| Position compensators | Drilling head and general topside equipment |

| Cable tensioner systems | Mooring systems |

| Wireline tensioner systems | Anchor handling brake systems |

| Rig tensioners | Wire tensioner systems (falls under motion compensation system) |

| Riser tensioners | Dive boat handling systems |

| Skidding systems | Lifeboat launching systems |

| Subsea ploughs | Pipe handling systems |

Common oil and gas products

| Rod seals | |||

512 |  513 |  605 |  621 |

| Wipers | |||

860 |  862 |  864 |  520 |

| Bearings | |

506 |  533 |