Characteristics and performance

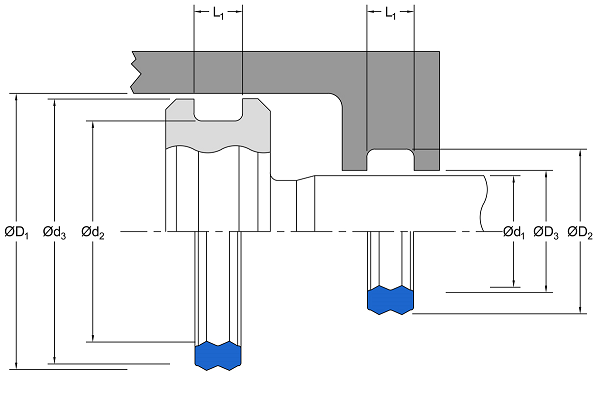

Hallite 668 twin lip static seal is designed to seal the joint between the gland and the cylinder bore or between the rod and the piston. The sealing element is a very effective replacement for the conventional O-ring and back-up ring combination in heavy-duty applications. The main advantage is its high groove stability compared to a conventional O-ring thus reducing fluid transfer caused by pumping.

Product details

Every nominal diameter of the Hallite 668 is suitable for a range of bore diameter, ØD₁ , or rod diameters, Ød₁.

The Hallite 668 is generally supplied as a bespoke part. Contact your local Hallite sales team for details.

Ask an expertMax pressure *

Temp range

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +39 (0)58 642 8287 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Not suitable | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Not suitable | Recommended |

| HFB (60/40 invert emulsion) | Not suitable | Recommended |

| HFC (water glycol) | Not suitable | Possible |

| Water | Not suitable | Recommended |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Recommended |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Not suitable | Recommended |