Specialist mining seal and bearing product knowledge

Technological advancements continue to push the limits of underground mining equipment. Increased seam cutting heights demand larger cylinder diameters and the rate of shearer operation needs to be maximised. Densely packed coal and potash formations and cavity roof loads place extreme performance requirements on shearers, longwall roof support systems, and related equipment. Productivity and efficiency are paramount to minimizing downtime and unscheduled maintenance.

Typical applications for mining seals

| Typical applications | ||

| Advancing ram | Excavators | Shield ram |

| Base lift ram | Longwall roof support systems | Shuttle cars |

| Crushing equipment | Mining haul trucks | Surface mining equipment |

| Cutting machines | Rock-breaker attachments | Tunnelling machines |

| Double telescopic legs | Roof bolters | Underground vehicles |

| Drilling equipment | Scoop trams | Wash plants |

| Drilling machines | Shearers | |

Durable hydraulic seal products for successful mining operations

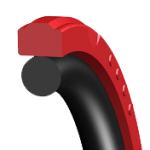

Operating requirements and service duty dictate the design of hydraulic systems and cylinders in the mining space. Fluid compatibility, lubricity, and contamination are all critical concerns for the optimal performance. The components within hydraulic systems must be built to ensure extended life cycles under extreme conditions.

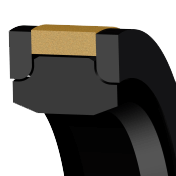

For speciality applications, we can also produce high-performance, large-diameter moulded and custom machined seals up to 600 mm diameter, with an extremely quick turnaround for delivery of spare parts for repair and refurbishment.

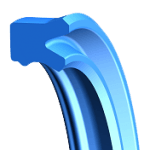

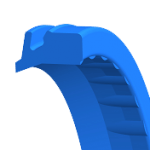

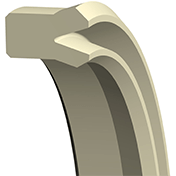

Common mining seal products

| Static seals |

155 |