Characteristics and performance

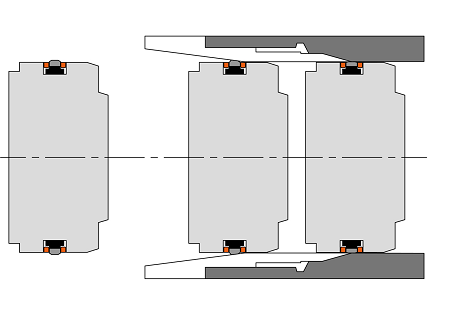

The Hallite 730 double-acting piston seal in a four part assembly is designed for use in heavy-duty applications where position holding ability is important, such as longwall mining roof support applications using water-based fluids and large diameter crane cylinders using standard hydraulic oils.

Comprised of a tough, wear resistant thermoplastic polyester elastomer (TPE) face seal pre-loaded by a profiled nitrile rubber energiser, the Hallite 730 design also contains a pair of rectangular polyacetal anti-extrusion rings.

The standard TPE face material is suitable for both roller-burnished and honed tubing. While rarely used in alternate material, the face material can be provided in a number of material options including lubricated polyester and PTFE.

product details

For your reference, we have included an installation guide for the Hallite 730 double-acting piston seal which you can find after the part number range pages of this data sheet.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on (02) 8886 1600 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Recommended | Recommended |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |