Characteristics and performance

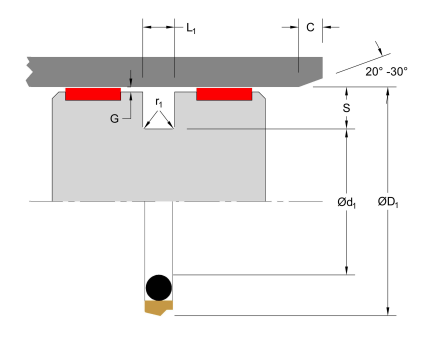

The Hallite P16 is a single-acting, o-ring energized, low-friction piston seal especially useful where smooth movement and location accuracy is required. The P16 design is based on the very successful R16 rod-seal design which has been proven in the market to be an excellent seal. High-performance Armorlene® materials, like HLX, provide outstanding wear and extrusion-resistance properties as well as large range of temperature and high-speed capabilities.

The P16’s design eliminates the potential for stick-slip and its very low running friction makes it ideal for high-speed applications. In particular, this seal is well-suited for use in piston accumulators in conjunction with other Hallite piston seals. The P16 is designed to fit a variety of inch and metric grooves, including ISO 7425-1 standard.

Product details

This seal is available in a variety of Hallite’s high-performance Armorlene® materials to suit a wide range of demanding applications. A tandem arrangement using the P54 or P16 in an Armorlene® material is effective in sealing high-frequency and long-stroke applications.

Max pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on (02) 8886 1600 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Possible | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |