Characteristics and performance

The proportions of the Hallite 520 wiping lip ensure that contact is maintained with the surface of the rod to remove heavily deposited containments such as mud and ice.

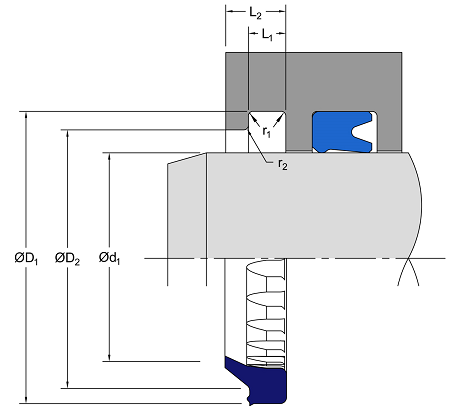

The outside diameter of the wiper incorporates a crush lip to provide an interference fit with the housing and a face bead to ensure that the crush lip is not trapped in the corner of the housing. These features help prevent contamination from entering the groove.

The moulded ribs on the internal diameter provide extra stability to the wiper and help prevent the possibility of blow-out due to pressure trapping between the wiper and the main rod seal.

The standard Hallite 520 is moulded in polyurethane for maximum wear resistance and performance. For heavy duty and more complex applications, it is also offered in a wide range of Hythane® polyurethane and polyester materials to provide the best ingression protection.

In harsher environments with heavy contamination, the Hallite technical team may advise you to use a Hallite 820 wiper for better debris ingress protection.

Product details

Ask an expertTemp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on (02) 8886 1600 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Recommended | Possible |

| HFB (60/40 invert emulsion) | Recommended | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Recommended | Possible |

| Other fluid types | ||

| Air/Nitrogen | Recommended | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |