Characteristics and performance

Manufactured in either a polyurethane or polyester shell energised by a high quality O-ring and designed for common North American square grooves. At zero or low pressure, the O-ring helps to increase the sealing force preventing any bypass. Under most conditions as the pressure rises, the sealing force increases and the O-ring ensures complete lip actuation.

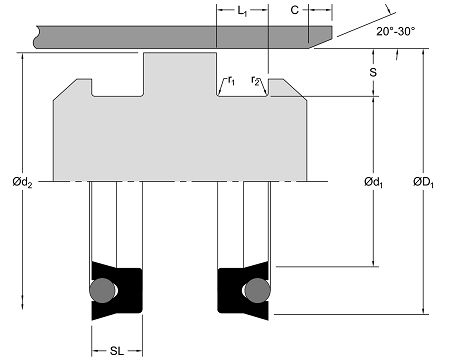

The symmetry of the Hallite 511 makes it ideally suited for single-acting rod and piston applications and its flexibility enables easy installation. The 511 can also be fitted back-to-back for use in double-acting applications.

Product details

Although the Hallite 511 can be used as a rod seal, other Hallite non-square rod seals are more suitable options, such as the Hallite 513, 605, or 621.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +91 80 2372 6000 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |