Characteristics and performance

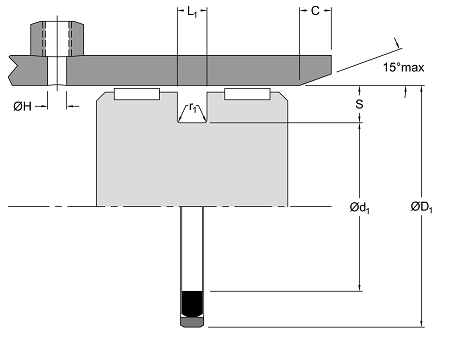

The Hallite 714 double-acting piston seal is a compact seal for medium to heavy-duty applications.

In double-acting telescopic cylinders or phasing cylinders, the seal’s reinforced, heat-stabilized, thermoplastic sealing face with step-cut joint is an ideal choice because it allows the seal to pass over ports without damage. The rugged, extrusion resistant design also performs extremely well in high-pressure off-highway and earth-moving applications where the seal face can tolerate the large extrusion gaps which are required to prevent piston-to-bore contact.

The abrasion resistant glass-filled nylon (GFN) face seal material allows the seal to work well on super smooth inside diameter (SSID) as drawn tube. The precision moulded face has chamfers which coupled with a profiled NBR expander allows for easier cylinder assembly.

Product details

The expander material comes in a number of material options to extend operating conditions. Contact your local Hallite technical team to decide which is best for your application.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on (02) 8886 1600 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Not suitable |

| Waterbased fluids | ||

| HFA (5/95) | Not suitable | Not suitable |

| HFB (60/40 invert emulsion) | Not suitable | Not suitable |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Not suitable | Not suitable |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Not suitable |