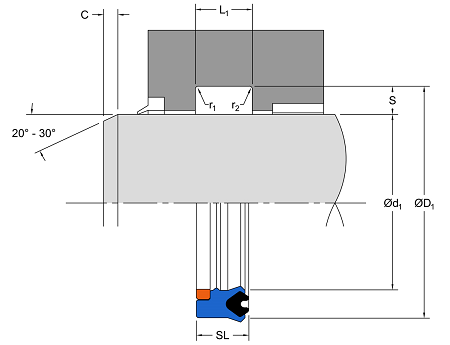

Characteristics and performance

The Hallite 621 is designed to provide a dry sealing solution in heavy-duty applications. The secondary sealing lip located behind the primary sealing lip improves stability of the seal in the gland. The unique profile of the NBR energiser ensures the precision trimmed primary sealing lips maintain contact under low or no pressure situations while ensuring proper sealing at higher pressures.

This unique profile is also used in the Hallite 622 twin lip rod seal. The Hallite 621 also incorporates an acetal anti-extrusion ring to withstand side loads and extreme pressure peaks even with the extrusion gaps, which are the result of using remote plastic bearing strips like the Hallite 506 or 708.

Product details

The Hallite 621’s seal shell is molded in Hythane® 181, Hallite’s high-performance polyurethane, for easy installation and excellent low temperature performance.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on (02) 8886 1600 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Recommended | Recommended |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |