Characteristics and performance

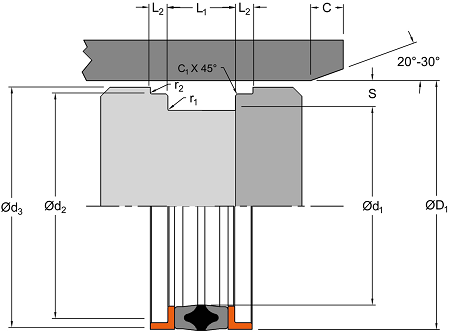

The combined nature of this seal enables the designer to use large clearances and, with the integral bearing rings, to restrict the piston length.

The assembly comprises a seal and two L shaped bearings. The centre of the seal is rubber which is bonded to two ‘U’ section bases of rubberised fabric, and is compressed by the housing to obtain an effective low pressure seal. When the pressure increases the rubber energises the ‘U’ section and deforms it to the housing, increasing the sealing area and improving the seal.

Rubberised fabric is used to protect the rubber, because it has strength and durability which combines with its ability to retain lubricant to help keep friction low and reduce wear.

Supporting the seal at either end is a polyacetal bearing proportioned to react to the pressure on the seal to prevent extrusion damage, and support the piston in its side load.

Product details

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +91 80 2372 6000 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Recommended |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Recommended |

| HFB (60/40 invert emulsion) | Recommended | Recommended |

| HFC (water glycol) | Recommended | Recommended |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Possible |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Possible | Possible |