Characteristics and performance

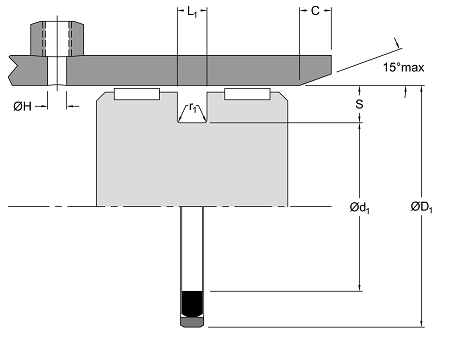

The Hallite 714 double-acting piston seal is a compact seal for medium to heavy-duty applications.

In double-acting telescopic cylinders or phasing cylinders, the seal’s reinforced, heat-stabilized, thermoplastic sealing face with step-cut joint is an ideal choice because it allows the seal to pass over ports without damage. The rugged, extrusion resistant design also performs extremely well in high-pressure off-highway and earth-moving applications where the seal face can tolerate the large extrusion gaps which are required to prevent piston-to-bore contact.

The abrasion resistant glass-filled nylon (GFN) face seal material allows the seal to work well on super smooth inside diameter (SSID) as drawn tube. The precision moulded face has chamfers which coupled with a profiled NBR expander allows for easier cylinder assembly.

Product details

The expander material comes in a number of material options to extend operating conditions. Contact your local Hallite technical team to decide which is best for your application.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +1 248-668-5200 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Not suitable |

| Waterbased fluids | ||

| HFA (5/95) | Not suitable | Not suitable |

| HFB (60/40 invert emulsion) | Not suitable | Not suitable |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Not suitable | Not suitable |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Not suitable |