Characteristics and performance

The Hallite 720 solves difficult assembly problems and can be a cost-effective alternative to the traditional piston assembly which has a separately fitted seal and bearing(s).

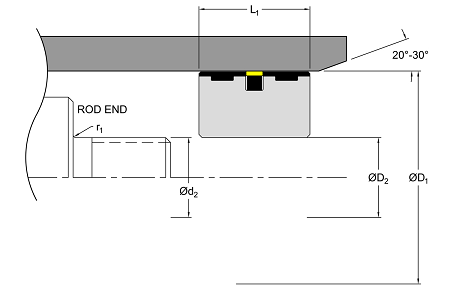

This seal improves stability and has smaller extrusion gaps that extend the life of the piston seal. Moulding the bearing material over the outer diameter gives an extremely tight fit between the piston and the cylinder bore. The piston diameter is tightly controlled which reduces the tolerance build up and results in increased performance.

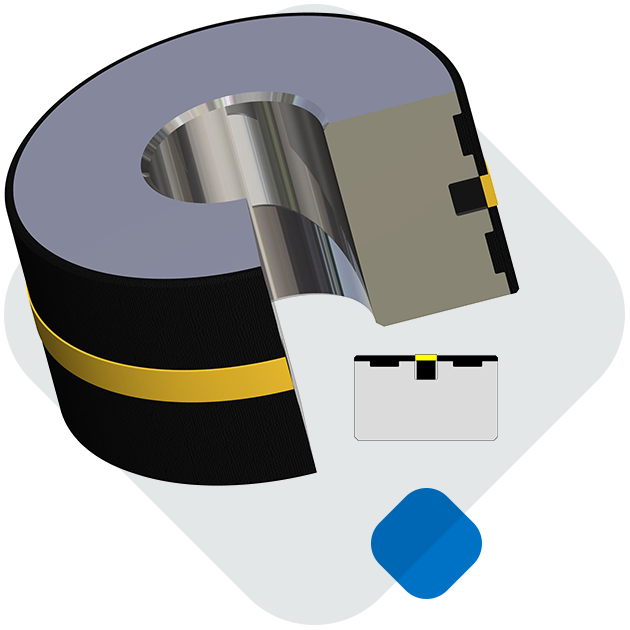

The Hallite 720 unitized piston is constructed using five components:

- High strength steel body

- Non-metallic bearing

- Rubber energiser

- Filled PTFE seal ring for inch sizes

- Polyurethane seal ring for metric sizes

Product details

The steel piston body is machined to exact dimensions. The non-metallic bearing material is moulded to the piston using a special proprietary process. It is then machined to the final precise outer diameter dimension to suit the cylinder bore and the seal is fitted. It is supplied ready to be attached to the piston rod for use in a cylinder.

In many cases the Hallite 720 is also supplied with an internal static sealing O-ring to provide a positive seal between the piston and the rod. Those marked with an asterisk in the part number range on the following pages do not have this internal seal.

The materials used in the standard unitised piston are selected to handle a broad range of application parameters. Contact your local Hallite technical team to decide which is best for your application.

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +44 208 941 2244 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Not suitable | Not suitable |

| HFB (60/40 invert emulsion) | Not suitable | Not suitable |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Not suitable | Not suitable |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Not suitable |

| HFD (Phosphate ester ARYL Type) | Possible | Possible |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |