Characteristics and performance

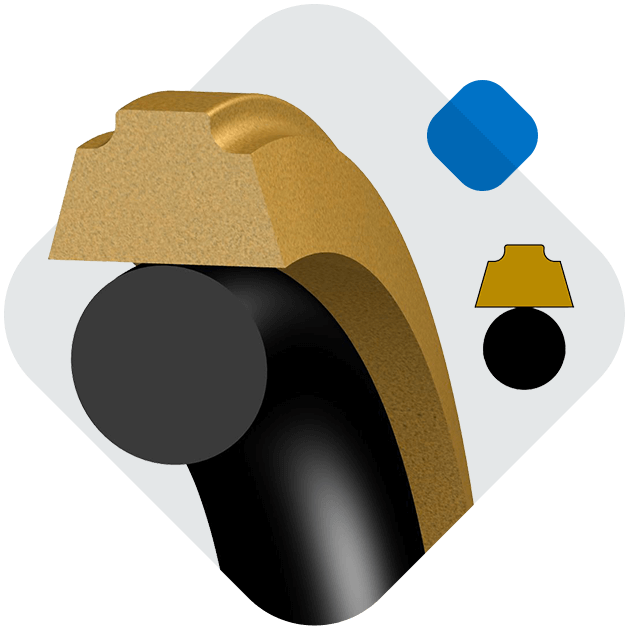

The product is a class-leading sealing solution for use in the most demanding applications. The standard P94 seal face employs a trapezoidal cross-section allowing optimal compression and load transfer to the seal face via the rubber energizer whilst being highly responsive to changes in pressure and/or direction of travel.

Uses include demanding, performance-critical applications such as injection moulding machines, machine tools, material handling, and hydraulic cylinders in a wide range of other industries.

Product details

The seal face is available in a range of materials from the high-performing Armorlene® series including HLX, a proprietary Hallite PTFE formulation which offers outstanding wear and extrusion-resistance properties and suitability for a wide range of operating conditions and fluid media.

Ask an expert

Max pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +44 208 941 2244 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Possible | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |