Characteristics and performance

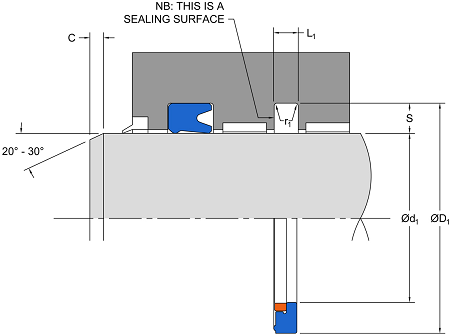

The Hallite 653 single-acting rod buffer seal is designed to be used in conjunction with a high-performance rod seal, such as the Hallite 605 and 621, to protect the primary seal from shock pressure loading and high frequency pressure spikes in the hydraulic system. The design allows oil to pass through to the rod seal while holding back pressure spikes also allowing pressure to pass back into the system preventing a pressure trap between the rod seal and the buffer seal. The Hallite 653 is an excellent pressure buffer option in heavy-duty applications, offering extended sealing system life and performance and is also interchangeable with common PTFE buffer seal housings.

This seal is moulded in Hythane® 181, Hallite’s high-performance polyurethane, for easy installation and excellent low temperature performance and offers a number of other high-performance polyurethanes, such as the Hythane® 361. The design also incorporates a polyacetal anti-extrusion ring to provide maximum extrusion resistance against shock pressure loads.

Product details

Ask an expertMax pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +44 208 941 2244 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Not suitable |

| Waterbased fluids | ||

| HFA (5/95) | Not suitable | Not suitable |

| HFB (60/40 invert emulsion) | Not suitable | Not suitable |

| HFC (water glycol) | Not suitable | Not suitable |

| Water | Not suitable | Not suitable |

| Other fluid types | ||

| Air/Nitrogen | Not suitable | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Possible | Not suitable |