Characteristics and performance

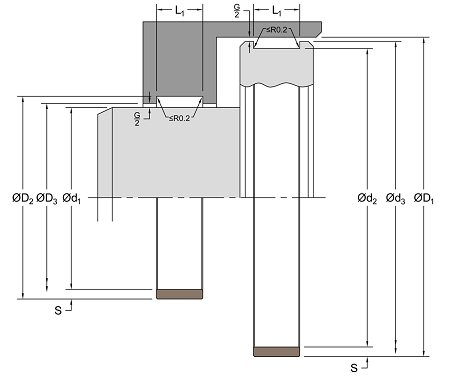

The Hallite 87 bronze-filled PTFE bearing strip is designed to provide an extremely effective, hard wearing, and easy-to-use bearing solution for lubricated or non-lubricated reciprocating, oscillating, and slow rotary movement applications. Hallite recommends using the Hallite 87 in light-duty applications and particularly for small diameters where the flexibility of the strip makes installation into a groove easier.

The low friction PTFE material reduces ‘stick slip’ between moving parts. The material is compatible with hydraulic mineral oil, lubricating oil, water based and synthetic fire resistant fluids and lubricating grease. It has excellent heat resistance and strength to resist creep. Although the material is rated at 200°C (390°F), the recommended maximum temperature for bearing applications is 60°C (140°F).

Product details

To view our Type 87 range including part numbers and technical data, please download the supplied datasheet by clicking here. For all other information about our Type 87 products, please contact your local Hallite sales office.

Ask an expertTemp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +49 (0)40 73 47 48-0 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Possible | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Recommended | Possible |

| HFD (Phosphate ester ARYL Type) | Recommended | Possible |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |