Characteristics and performance

High-performance Armorlene® materials, like HLX, provide outstanding wear and extrusion-resistance properties as well as large range of temperature and media compatibility. The P54 has a proven design pedigree as a high-performance seal used in demanding applications.

The standard P54 seal face includes pressure notches, which makes the seal very responsive to changes in pressure or direction of travel. Used successfully for years in performance-critical applications in construction equipment, machine tools, material handling, agricultural equipment, and other industries, the Hallite P54 is a workhorse compact, double- acting, piston-sealing solution.

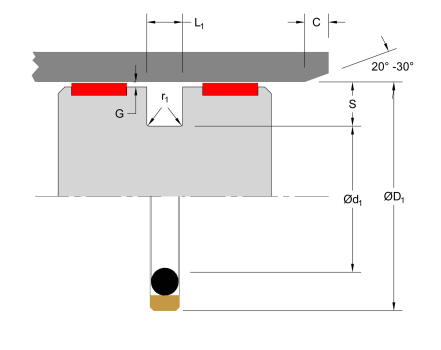

The seal’s design fits a variety of housing sizes, including ISO 7425-1 grooves, and is offered in a wide range of metric and inch options. Hallite recommends proper guidance be used with this seal in heavy-duty applications (see Hallite Bearings section).

Product details

This seal is available in a variety of Hallite’s high-performance Armorlene® and Hythane® materials to suit a wide range of demanding applications.

Max pressure *

Temp range

Max speed

* Max pressure stated is dependant on the material variant selected. Please consult the datasheet for further information.

- Recomended

- Possible

- Not suitable

* For fluid types marked as possible, please call our team of experts on +49 (0)40 73 47 48-0 to talk through your requirements and determine if this seal is the most suitable for your needs.

| Dynamic application | Static application | |

|---|---|---|

| Fluids based on mineral oil | ||

| Any | Recommended | Possible |

| Waterbased fluids | ||

| HFA (5/95) | Possible | Possible |

| HFB (60/40 invert emulsion) | Possible | Possible |

| HFC (water glycol) | Possible | Possible |

| Water | Possible | Possible |

| Other fluid types | ||

| Air/Nitrogen | Possible | Not suitable |

| HFD (Phosphate ester ARYL Type) | Not suitable | Not suitable |

| Synthetic esters (HEES, HFDU) | Recommended | Possible |